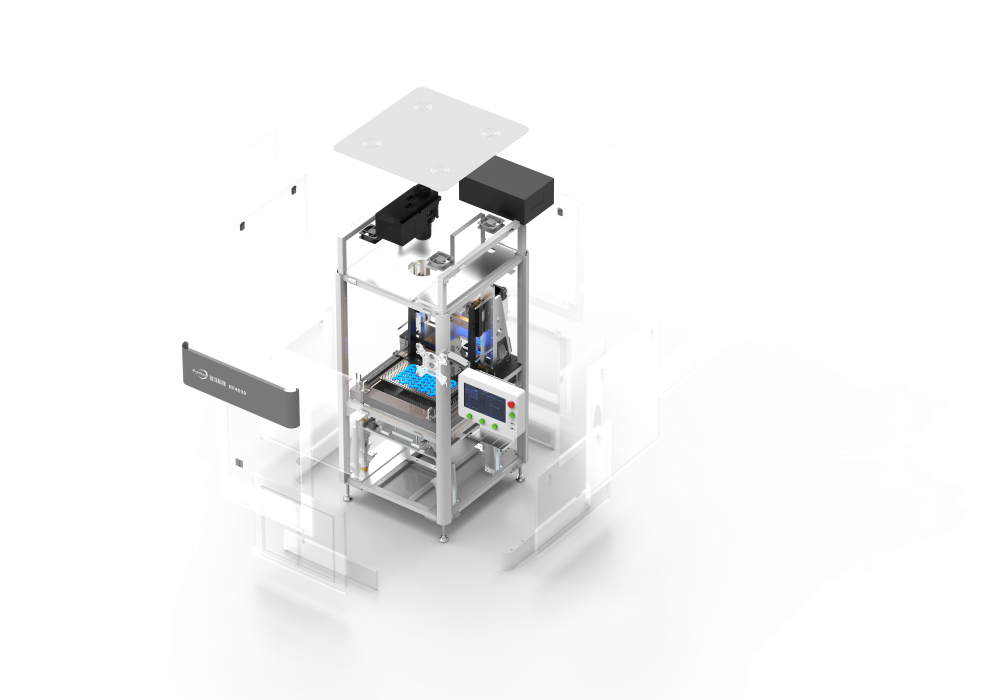

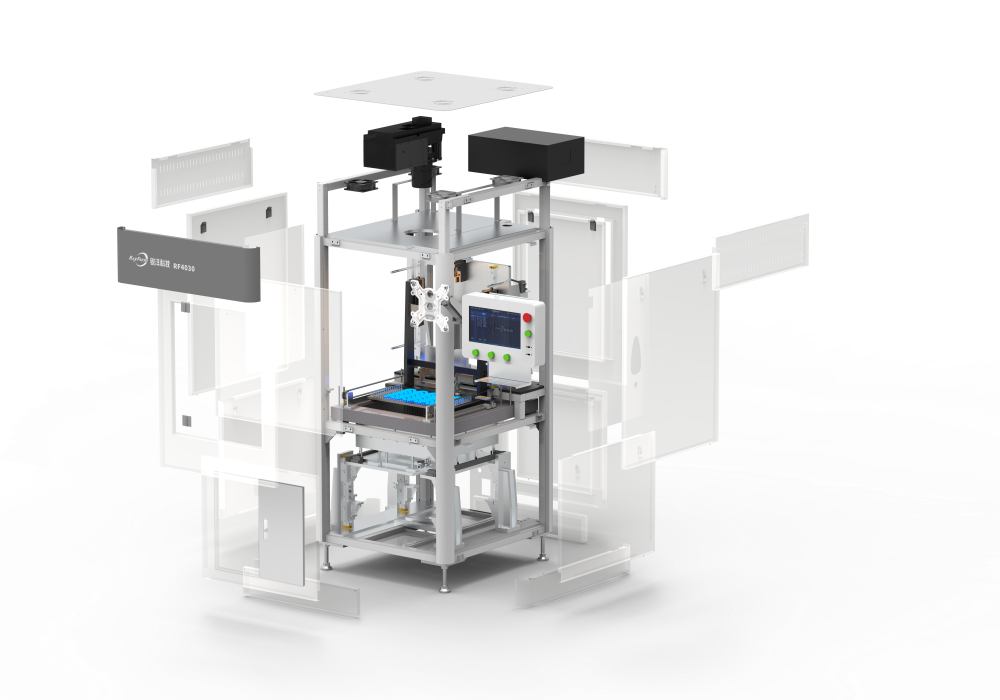

3D Printer

RF4030

Fast and efficient DLP technology printer, suitable for dental, orthopedic and other fields

The RF4030 Series 3D printers boast a fully automated system, featuring capabilities for automatic removal, sorting, refilling, task assignment, and printing. It adopts multi-matrix DLP technology, sinking platform mode, and its mechanical design innovative reduces the peeling force, safeguarding dental models, enhancing stability, and ensuring clean removal. Moreover, its superior design ensures high reliability, stability, and straightforward maintenance,high efficiency on the market.

Main Advantages

Advanced HADPm technology, the large DLP build volume 384*216mm

25 dental models printed in 35 minutes,the highest efficiency in mass production

7x24 hours unmanned-automated production with PMS

4K DLP optical engine,with more than 30,000 hours of life time

RF4030 Series Specification

|

Printing Technology |

DLP |

|

Build Volume |

384x216x1260 mm |

|

X-Y Resolution |

100/65 μm |

|

Build Precision |

80 μm |

|

Print Speed |

30mm/h |

|

Resolution |

3840 × 2160 HD |

|

Projection Mode |

Top-down Projection |

|

Network Type and Protocol |

WiFi, Ethernet Using MQTT, HTTP, TCP, UDP, FTP |

|

Power |

3.0kw |

|

Light Source Lifetime |

>30,000 hours |

|

Temperature Range |

22–30 °C(72–86 °F) |

|

Relative Humidity |

< 55% |

|

Machine size(W x D x H) |

829x885x1930mm |

|

Machine weight |

400 KG |

|

Processing and Finishing |

Post-Curing Unit (optional) |

|

Warranty |

2 year |

Relevant Resin

Rayform have developed high Temperature resistant resin, water washable resin and also washing-free resin for our printers,they are designed for the thermoforming process and easy post-processing.Such Material based on methacrylate resin for DLP with 385nm/ 405nm LED and LCD systems. High form, brake stability, abrasion, moisture, and light resistance along with a smooth matte surface finish, makes it perfect for dental model making.