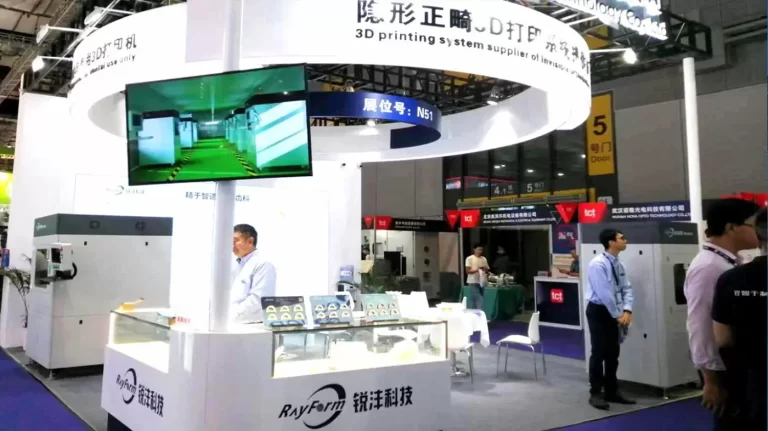

RayForm Technology will participate in IDEC 2025 in Jakarta, Indonesia, to showcase our latest high-precision dental 3D printing systems and dental-specific photopolymer resins.

For dental labs, DSOs, clear aligner manufacturers, distributors, and educators looking to scale digital dentistry, IDEC 2025 is a practical place to see solutions live, compare technologies side by side, and meet our technical team face to face.

In this announcement, you will find what IDEC 2025 is about, who should visit our stand, and how our hardware + resin + process + service package can support your digital production roadmap.

IDEC 2025: why this event matters for digital dentistry

Indonesia Dental Exhibition & Conference (IDEC) is Indonesia’s premier dental trade exhibition and conference, jointly organised with the Indonesian Dental Association (PDGI). According to the official Indonesia Dental Exhibition & Conference website[1], IDEC brings together local and international dental brands, key opinion leaders, and thousands of dental professionals.

The 4th edition of IDEC will take place from 14–16 November 2025 at the Jakarta International Convention Center (JICC), with a three-day exhibition and scientific conference focusing on “Transformation of Dental Health Resilience”.[1][2][3]

For visitors, this means:

- One-stop platform to explore digital imaging, CAD/CAM, 3D printing, and AI-assisted solutions in a single venue.[1][2]

- Rich scientific program featuring lectures, hands-on workshops, and localized educational content tailored to Indonesian dental practice.[1][2]

- Regional networking hub where dentists, dental students, hospital decision-makers, manufacturers, and distributors connect around new technologies and business models.[2][3]

If you are planning your investments in digital dentistry for the next 2–3 years, IDEC 2025 is an efficient way to compare options and validate partners on the ground.

RayForm’s exhibition focus: from printers and resins to full workflows

Shenzhen RayForm Technology Co., Ltd. is a specialist in high-precision dental 3D printing systems and photopolymer resin materials, with a focus on clear aligner and restorative applications.We do not only offer stand-alone equipment or resins—we deliver an end-to-end digital production solution covering hardware, materials, processes, and service.

At IDEC 2025, we plan to highlight three core pillars:

- High-precision dental 3D printers

Our printer portfolio (e.g. RF-8800, RF-4030, RF-4050) is built on the proprietary HADP™ multi-engine super array architecture designed to deliver high accuracy, high throughput, and high stability for dental applications. Visitors will see how this architecture supports:

- Stable dimensional accuracy for complex geometries.

- High-volume model and aligner model production.

- User-friendly interfaces and intelligent nesting to reduce operator workload.

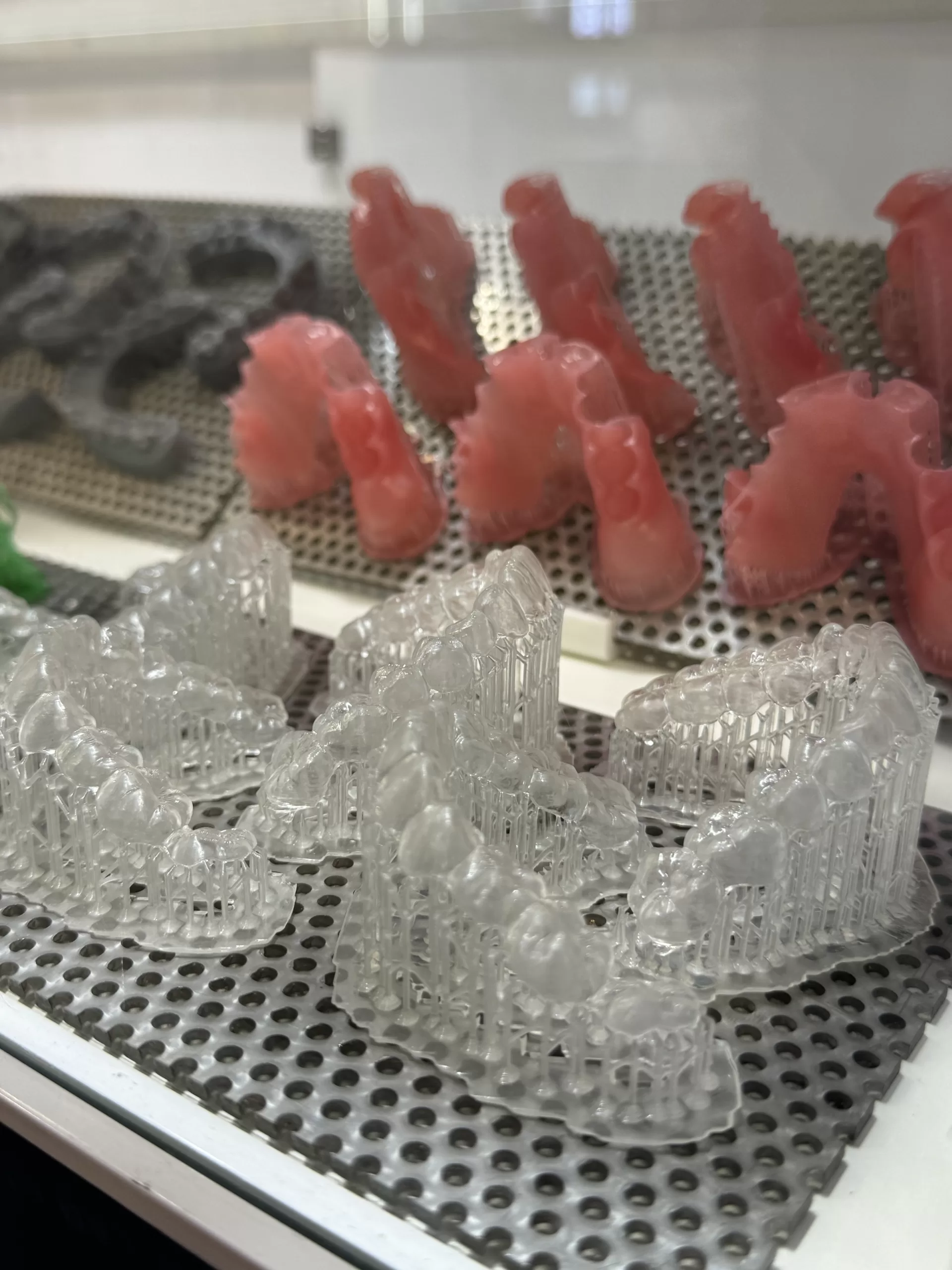

- Dental-specific 3D printing resins

RayForm provides resins for models, surgical guides, denture bases, temporary crowns and bridges, splints, and night guards, validated on mainstream LCD/DLP printers At IDEC 2025, we plan to showcase:

- Orthodontic model resins with high heat deflection temperature (HDT) and smooth surfaces for thermoforming.

- Restorative and temporary materials designed for strength, wear resistance, and biocompatibility.

- Open-materials strategy so you can adopt RayForm resins on existing compatible printers.

- Standardized processes and cost transparency

Many dental labs and DSOs struggle not with “whether they can print,” but with yield stability and true cost per part. At our booth, you will see:

- Standardized printing parameter sheets and post-processing SOPs.

- Demo of a cost-per-part calculator to understand machine, resin, labor, and reprint impact.

- Application-specific packages for clear aligners, restorative work, and surgical guides

| Visitor profile | What you’ll see at the RayForm booth | Key takeaway | IDEC 2025 benefit |

|---|---|---|---|

| Dental labs | Live demos of model and aligner model workflows | How to stabilize yield and minimize reprints | Compare multiple 3D workflows in one hall |

| DSOs & production hubs | Batch production setups and process standardization examples | How to roll out unified workflows to many sites | Meet other multi-site operators |

| Distributors & dealers | Product lines, packaging, and documentation | How to add validated dental resins to portfolio | Scout brands and negotiate partnerships |

| Universities & training | Teaching kits and parameter sheets | How to build reproducible teaching cases | Discover speakers and training formats |

Evidence, data, and how we support your decision-making

RayForm’s approach is built from the customer’s perspective—whether you run a small lab or a multi-site DSO network. At IDEC 2025, we aim to give you concrete data rather than marketing slogans.

- Results summary

- Printers and consumables designed to comply with ISO 9001-based quality systems and international regulations such as CE, FCC, and FDA where applicable.

- Process windows and SOPs structured so labs can move from “experience-driven” to data-driven batch production.

- Cost tools that help you model per-unit cost for aligner models, guides, temporary restorations, and splints.

- Risks & mitigations in digital dental production

- Risk: Unstable print accuracy and repeatability.

- Mitigation: Use verified process windows, comprehensive parameter sheets, and QC checkpoints along the workflow.

- Risk: Underestimated total cost of ownership.

- Mitigation: Include machine depreciation, resin consumption, labor time, and reprint rates in your calculations.

- Risk: Documentation gaps for regulatory or purchasing teams.

- Mitigation: Work with suppliers that provide full MSDS, TDS, ISO, and where applicable regulatory documentation for review.

- Implementation checklist (what to bring to our booth)

- A rough estimate of your monthly model or clear aligner case volume.

- Your current printing or manual workflow (even if it’s only partially digital).

- Key questions from your management, such as ROI expectations, rollout timelines, or regional expansion plans.

Independent coverage of IDEC 2025 highlights how the show is becoming a flagship platform for strengthening Indonesia’s dental health resilience and promoting digital transformation across the sector.[2][4] Reports from Dental Tribune International[2] and Dental Asia[4] underline the event’s focus on innovation, collaboration, and education—exactly the context in which RayForm solutions are designed to perform.

FAQs and practical concerns

Q1. When and where will IDEC 2025 take place?

IDEC 2025 will run from 14–16 November 2025 at the Jakarta International Convention Center (JICC) in Jakarta, Indonesia.[1][2][3] The exhibition and conference are scheduled across three full days, with opening hours published on the official IDEC website.

Q2. Who should plan to visit the RayForm booth?

Our booth is ideal for dental labs, DSOs, central production centers, 3D printer brands seeking validated dental resins, distributors building a dental materials portfolio, clear aligner manufacturers, and educational or research institutions. If you are evaluating 3D printing for clinical production, or optimizing an existing line, we encourage you to meet our team.

Q3. How can I register for IDEC 2025?

Visitors can pre-register online to secure free admission, as the official visitor registration page allows you to skip the onsite registration fee.[1][5] We recommend early registration to avoid queues and to receive event updates from the organizer.

Q4. Will RayForm provide live demos or only static displays?

Our goal is to show complete digital workflows, not just hardware on a stand. Subject to final scheduling, we plan to run workflow demos—from data preparation through printing and post-processing—so visitors can see real cycle times, handling steps, and quality outcomes.

Q5. Does this exhibition announcement replace regulatory or clinical guidance?

No. IDEC 2025 and the RayForm booth are intended for dental professionals and industry partners. Nothing in this announcement constitutes clinical, regulatory, or legal advice. Always follow local regulations and professional guidelines, and consult qualified experts before clinical implementation.

Conclusion and next steps

IDEC 2025 will be a key moment for Indonesia and the wider ASEAN region to accelerate digital dentistry, with a strong emphasis on innovation, resilience, and collaboration.[1][2][4] For RayForm, the exhibition is an opportunity to demonstrate how our high-precision printers, dental resins, and standardized processes can help labs, DSOs, and partners scale digital production with confidence.

To make the most of your visit:

- Pre-register for IDEC 2025 via the official visitor information page[5].

- Schedule a meeting with the RayForm team in advance to discuss your volumes, workflow, and plans—so we can walk you through a tailored implementation checklist.

- Bring your questions about printer-resin compatibility, process validation, and multi-site rollout; our team will be ready with data, documentation, and practical examples.

We look forward to welcoming you at IDEC 2025 in Jakarta and exploring how we can become your most reliable technology partner in the era of digital dentistry. This article structure follows our internal SEO content guidelines to support clear and actionable information for readers.

References

- Indonesia Dental Exhibition & Conference — official website

- Dental Tribune International — IDEC 2025 to advance dental innovation and collaboration in Indonesia

- Infodent International — IDEC 2025 calendar listing

- Dental Asia — Approaching IDEC 2025: innovation and global collaboration driving Indonesia’s dental health transformation

- Indonesia Dental Exhibition & Conference — I Want to Visit (visitor registration & why visit)